ABOUT US

Custom Product Innovations (CPI) is a third-generation manufacturer located just outside of St. Louis. Our manufacturing capabilities include foam molding, foam cutting, sewing, fabric cutting, silk screening, and UV printing.

With over 25 years of experience, CPI manufactures products for both the Aerospace and Defense Industry and Fitness Industry. Our commitment to quality and value have earned CPI a great reputation from existing customers and suppliers, which we don’t take lightly.

In addition to manufacturing, CPI specializes in product development – particularly within the Fitness Industry. CPI began making Total Gym® benches and has successfully launched dozens of new products with millions of units sold. Our flagship brand in the Fitness Industry is AbMat®.

CAPABILITIES

Foam Molding: integral-skin, flexible, and visco-elastic integral-skin foam of all shapes, sizes, and durometers.

Foam Cutting: fabricate a variety of foam types including the following: polyurethane, polyethylene, crosslink polyethylene, EVA, and molded foams.

Sewing: sew complex, high-spec driven parts. Sew hundreds of thousands of units annually. All components are machine-cut, reducing scrap and holding tight tolerances.

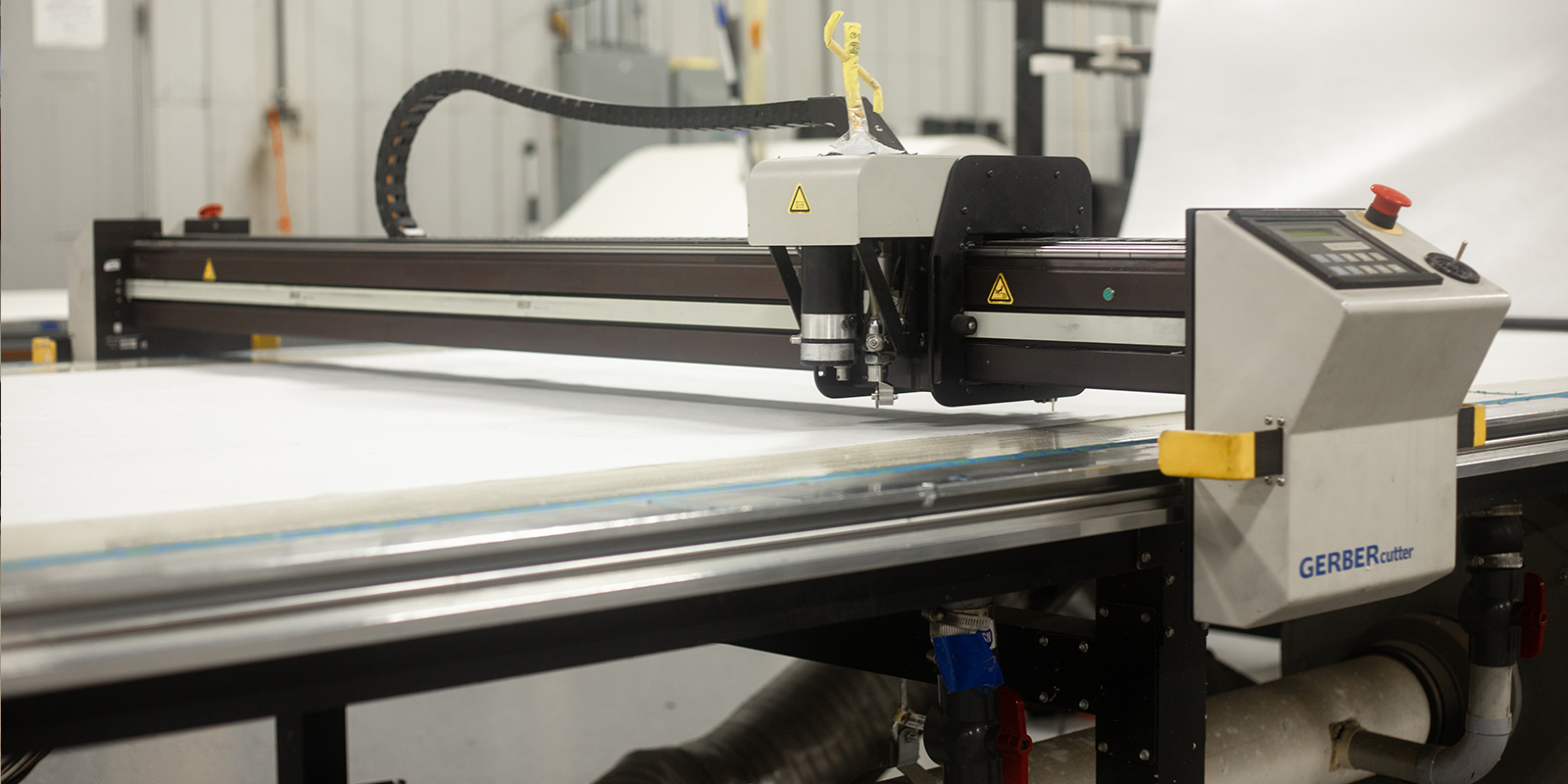

Fabric Cutting: cut a variety of materials including the following: woven and non-woven fabric, expanded and non-expanded vinyl, Cordura, Nomex, rubber, crosslink foam, and reinforced silicone.

Silk Screening: use a variety of inks depending on the substrate. We print on a variety of fabrics including vinyl, foam, wood, and rubber.

UV Printing: print multi-color, high definition prints on three dimensional objects including vinyl, metal, wood, and rubber.

Product Development: develop products from idea to product launch. See here for more information.

The AbMat® team has vast experience developing and manufacturing innovative fitness accessories. Our in-house creative team makes us nimble and relevant in today’s digital age.